Bistable electrowetting displays

Electrowetting displays, which are based on controlling the shape of a water/oil interface by an applied voltage, were first reported in 1981.1 However, it took two decades until Liquavista introduced the first prototypes,2 which were followed several years later by the first bistable electrowetting approach.3 A number of features and advantages make electrowetting displays highly attractive and promising for a wide range of applications, from LED replacements to e-readers and billboards. These include their reflective technology (resulting in low power consumption), high transparency (implying high ambient-light performance), reflective, transflective, and transmissive modes, and subtractive and additive colors for easy color matching.

At Advanced Display Technologies (ADT), we developed electrowetting ‘droplet-driven display’ (D3) technology. Contrary to charge-based technologies such as electrophoretics, it exhibits true bistability (since no electrical refresh is needed). It also features paper-like white appearance in the ‘off’ state, passive-matrix driving3 for low-cost and flexible plastic substrates (which is easier to achieve than an active-matrix approach), and optimization for large pixel sizes (from 0.5 to 10mm).

Figure 1 presents the technology's basic principle, where a water droplet is surrounded by oil (in reality, special liquids are used to achieve a wide temperature range). The ‘pixel’ consists of two glass (or plastic) substrates with structured indium tin oxide electrodes, similar to an LCD. The electrodes are covered by a dielectric layer which is coated with a hydrophobic film. The latter forces the water droplet to contract (left and right, bistable) while an electric field causes it to relax. By controlling the bottom electrodes (red), the droplet can be moved from left to right, and vice versa. This principle is adapted in conjunction with various geometries.

By applying the bistable-electrowetting principle, we can produce displays with pixel sizes from 0.5 to 10mm. The simplest versions are LED replacements (see Figure 2), which have benefits in terms of no power consumption (except for state changes for approximately 1s), readability in sunlight conditions, and status visualization during power failures. Other low-resolution versions include 5×7 pixels2 character displays (see Figure 3).

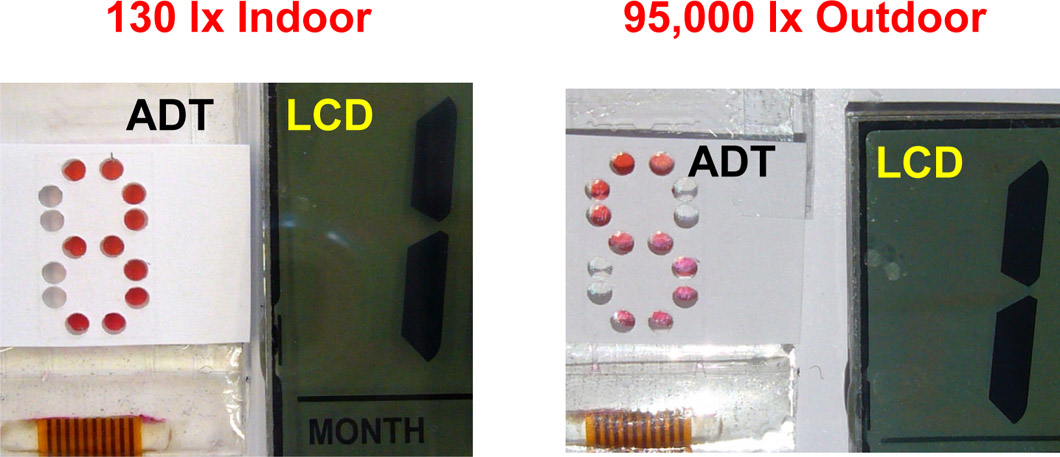

Since electrowetting can be used with large pixel sizes, subtractive color mixing by stacking cyan, magenta, and yellow layers is possible and feasible (see Figure 4). The major advantages are vivid colors and a printer-like color range for billboards. An important issue for all kinds of displays is readability in various ambient lighting conditions (see Figure 5), ranging from indoor settings to bright sunlight. The image quality of emissive displays such as plasma and backlit LCD screens degrades with increasing illuminance. Reflective technologies have advantages, but most of those approaches lack good color reproduction (wide gamut). The ADT displays are readable from dark-room ambient-light conditions (backlit, which is not possible for other reflective-display technologies like electrophoretics) to pure reflective indoor and outdoor conditions.

We have developed a range of bistable displays based on electrowetting, and recently established a production company. Our displays are suitable for use in a wide range of applications, from LED replacements to electronic large-area billboards. ‘No power,’ sunlight readability, a wide temperature range, and excellent color reproduction are among their unique features. Other current efforts by our team include integration of in-cell touch functionality, as well as system and production improvements.

Karlheinz Blankenbach joined Pforzheim University as a full professor in 1995 and founded the Display Laboratory. His main research and development efforts are in display driving and systems, as well as display metrology. He is chair of the Electronic Displays Conference and member of the board of the German Flat Panel Forum.

Juergen Rawert is a pharmacist and holds an MBA degree. He worked for 10 years in research and business development at Degussa AG. He successfully participated in setting up several startup companies before joining ADT as business-development director.