Realization of ceramic ultrashort-pulse lasers for microfabrication

Use of ultrashort-pulse lasers for the generation of pico- and femtosecond pulses has attracted considerable attention for a wide range of industrial applications. Research has shown that ultrashort-pulse laser systems using titanium:sapphire (Ti:S) crystals are very efficient for micromachining in laboratories. Although Ti:S lasers are commercially available, their energy efficiency—the conversion rate of electrical power to ultrashort-pulse radiation—is very low (generally less than 0.5%). The reason for this is that Ti:S lasers require an inefficient green laser for pumping the lasing crystal, so that their efficiency cannot be better than that of the pump laser. A complicated laser system also causes instabilities because of mechanical vibrations and changes in temperature.

In industrial settings, carbon dioxide lasers are generally used because of their high efficiency (>10%) and low initial cost. This 20-fold difference in efficiency has resulted in the huge sizes and low output power of commercially available Ti:S laser sources, because the power supplies needed for Ti:S lasers are bulky. In addition, the high initial and running costs, as well as the size of the cooling systems required to deal with the large amounts of heat generated are also problematic. Despite the technology's numerous potential applications, ultrashort-pulse Ti:S lasers are, therefore, currently only used in settings where high costs per photon are acceptable, such as for drilling of the fuel nozzle in high-performance car engines.

Ytterbium (Yb)-doping could be used to realize a practical, ultrashort-pulse laser system. The main advantage of using Yb-based lasers is their simple energy-level structure. The pumping and lasing wavelengths of Yb:yttrium aluminum garnet (YAG) sources are 940 and 1030nm, respectively. Since this wavelength difference is very small (smaller than for conventional neodymium-doped YAG lasers), the energy efficiency can be high: the maximum energy-conversion efficiency is determined by the ratio of both wavelengths. In addition, 940nm pumping light is obtained directly from the system's laser diode. The device does not need a green laser and, therefore, can be made compact. A significant disadvantage is related to the thermal management of the laser crystals because of the laser transition to the ground state. To obtain high Yb-laser performance, cooling of laser crystal is very important. A temperature increase causes an increase in the population of the final state of the laser. We have investigated the potential of Yb-doped single crystals such as Yb:YAG, Yb:yttrium orthovanadate (YVO4) and Yb:potassium gadolinium tungstate (KGW). Here, we focus on a new ceramic material.

Using YAG, high transparency, low scattering, and high resistance to thermal heat has been realized.1 We investigated the laser performance of ceramic Yb:YAG, measuring basic laser performances at room temperature. When we pumped the laser with 13.8W power at 940nm, it produced 6.8W output power with 72% slope efficiency.2 We obtained wavelength tunability from 992.52 to 1110.83nm with SF11 prisms, a much wider passband than we had achieved previously.3 These results show the great potential of ceramic laser-crystal applications. We also demonstrated ultrashort-pulse generation with a ceramic material. The laser generated 233fs pulses at 1030nm with a semiconductor saturable-absorber-mirror device. To the best of our knowledge, this is the first time that femtosecond-pulse generation has been demonstrated with a ceramic laser source.

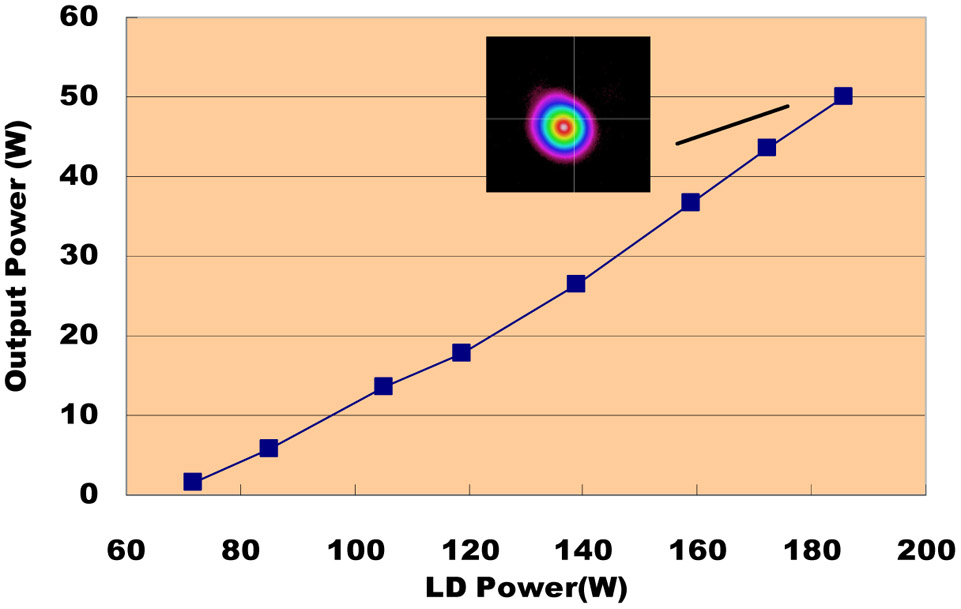

Our ceramic Yb:YAG laser also exhibits good characteristics as an amplifier. We used a simple ceramic Yb:YAG rod pumped by fiber-coupled continuous-wave diode lasers from both ends of the rod. The laser rod was cooled with water. The laser oscillator, which contained two laser heads, produced over 50W with an optical efficiency of 30% (see Figure 1). The regenerative amplifier was equipped with a barium borate Pockels cell with a quarter-wave voltage synchronized to the mode-locked pulse train from the Yb-fiber oscillator. Upon seeding by this oscillator (200mW average power, 200fs pulse duration, 40MHz repetition rate), we obtained a 2.3ps pulse with an average power of 20W at 100kHz at room temperature and achieved an efficiency of more than 10%.4 For pulse stretching, our very simple and compact laser system used the optical fiber connecting it to the Yb-fiber laser.

We will next implement a tandem laser head, for which we expect 50W output, while application of an oscillator and multiple amplifiers is expected to generate over 100W ultrashort-pulse lasers with 10% efficiency. These performance levels satisfy the conditions for practical use of ultrashort-pulse lasers for microfabrication.

Satoshi Wada obtained his PhD from Tokyo University of Science (Japan) in 1992. He has since been unit leader of the optical green-technology research unit. In 2007, he was appointed as professor at Tokyo University of Science. His research focuses on nonlinear optics, solid-state lasers, and laser applications.