Patents: The electro-optic supermarket – Will it ever arrive?

The amount of administration, logistics and record-keeping required to run even a medium-size retail establishment is daunting. To perform such tasks manually would be impossible in today's large retail stores and supermarkets. Although great strides have been made in improving the operational efficiency of 'big box' establishments over the past few years, much more remains to be done before such establishments can rid themselves from many of the manual, mundane tasks, which require significant time and labor and are subjected to costly human errors.

The amount of administration, logistics and record-keeping required to run even a medium-size retail establishment is daunting. To perform such tasks manually would be impossible in today's large retail stores and supermarkets. Although great strides have been made in improving the operational efficiency of 'big box' establishments over the past few years, much more remains to be done before such establishments can rid themselves from many of the manual, mundane tasks, which require significant time and labor and are subjected to costly human errors.

Microprocessor-controlled electronic cash registers and UPC/bar code scanners appeared in some retail establishments during the 1960s and 70s. The systems greatly improved the speed and accuracy of record-keeping, inventory control and other back-office tasks, but left much of the produce and merchandise handling to slow, inaccurate labor-intensive processes. Two new technologies have arrived, with the capability to substantially increase supermarket efficiency. These technologies are radio frequency identification (RFID), and a subset known as electronic shelf labels (ESL).

RFID allows the tracking of individual items from source to destination -- from delivery vehicle to warehouse storage, from warehouse storage to retail shelves and from retail shelves through the cash register and out the door. Combined with GPS capability, real-time long distance tracking can be accomplished. But even beyond location data, RFID is capable of storing and processing information regarding the item's size, weight, condition and other attributes. One such example would be the monitoring and storing the temperature of perishable items (meat, fish, etc.) during transit, along with date/time stamp information, and signifying an alarm condition if tolerable parameters have been exceeded.

So, what has inhibited the use of RFID technology in the retail industry? In a word - cost. It is hard to justify the replacement of a plain tag, which costs pennies, with an electronic RFID tag costing significantly more, even when considering the value-added aspects. A big part of the RFID expense is in the device packaging. Until recently, RFID devices were fabricated using costly semiconductor manufacturing techniques. Now, however, organic thin-film, printable substrates are replacing the more expensive ultra-pure silicon wafers along with the associated semiconductor deposition and lithographic fabrication techniques. Organic RFID tags can now be printed on a flexible substrate using special conductive inks. This has resulted in a substantial reduction in device cost and is making the technology more attractive to the retail community.

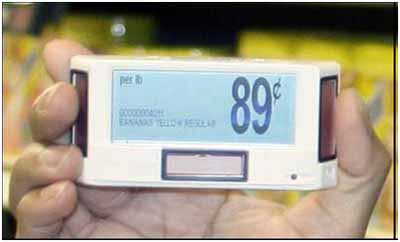

Figure 1. Typical Electronic Shelf Label Display (Altierre Corp.)

Recently, an RFID-based device known as Electronic Shelf Label (ESL) has come on the scene with the promise of streamlining the shelf-stocking and merchandise-displaying processes (Figure 1). These labels replace paper labels and offer an impressive array of advantages to the retailer, such as:

- Wireless real-time, store-wide, error-free price adjustments

- Ensures price accuracy from shelf to checkout; eliminates the need for 'price checks' at checkout register

- Eradicates many thousands of hours per year updating paper labels by hand

- Allows instantaneous announcement of short-term sales promotions

- Attracts buyers using various colors and/or pulsating price displays to highlight special sales offers.

The electro-optic display technology for ESL devices is most commonly liquid crystal. It is important that the display be thin, flexible, lightweight, power-efficient, having a high contrast ratio and excellent readability in a bright ambient. It would be a great advantage if it also had multiple colors without the need for filters, and would support reversible and irreversible coloring operation. Ideally, it should be capable of integration with RFID components, batteries and discrete and integrated electronics on the same substrate. NanoChromics(TM) has patented an LCD display based on solid-state electrochromic phenomena incorporating advanced molecular technology and nanomaterial formulations. Their display can be manufactured using a wide range of techniques, including flexography, silkscreen and inkjet printing.

As is the case with many RFID devices, cost is an inhibiting factor to the acceptance of ESL technology. ESLs costs more than paper labels, but that in itself can be misleading. Several states (California, Illinois, Massachusetts, Michigan, New Hampshire, North Dakota, Rhode Island and sometimes in Connecticut) have adopted an Item Pricing Law (IPL) which says that each item must have its own individual price tag, or sticker. In other states, a single price tag on the item's shelf is sufficient. This leads to a significant disparity between IPL and non-IPL prices. A study in 2007 by Paul Rubin et al. examined the cost impact of transferring from paper labeling to ESL technology. The data showed that "...prices in IPL stores are approximately 20 cents to 25 cents higher per item than in non-IPL stores. Stores in Connecticut with [ESL] were in the middle, with prices 15 cents lower than in IPL stores, and 10 cents higher than in non-IPL stores."

In addition to the cost of the devices, markets must also consider the cost of installing an infrastructure to operate the store-wide ESL system. Wireless transmission is required to minimize the amount of wiring associated with hundreds of ESL displays. One of the most efficient methods is to use the store's internal lighting system as a transmission media. Such a system is described in U.S. patent no. 5,635,915, "Transmission System." Inventor Trevor Gray describes a method whereby the product pricing information is transmitted to the ESL devices by phase modulating the source supplying power to the store's lighting system located near the ESLs to be updated.

Although battery technology has advanced tremendously in the past few years, the process of monitoring and periodically replacing or recharging batteries can create a logistical nightmare, especially when thousands of ESL devices are involved. The circuit designers have done a good job reducing the power consumption to microwatts; but eventually, all batteries need recharging or replacing. Further advances are being made to extend the present 5-year battery life out to 10 years and beyond by utilizing ultra-low power circuitry, 'sleep' modes, low transmission duty cycles, and other power-saving techniques. One typical technique is described in U.S. patent no. 7,073,081, "Methods and apparatus for conserving battery power in an electronic shelf label system." Inventors Kevin Haulk and Cheryl Harkins describe a method of removing power from particular ESL circuits not scheduled for use at specific periods of time, thus reducing the power consumption of the device.

Batteries are also costly and can be relatively large when compared to the overall size of an ESL device, especially rechargeable Lithium Ion (Li-Ion) batteries. Lately however, a new class of batteries, developed by NEC (Japan), uses what is known as Organic Radical Battery (ORB) technology. Fully rechargeable in 30 seconds, its thin (less than 300 micron), flexible (as a sheet of paper) and cut-to-fit properties make it ideal for embedding into RFID and ESL devices.

Not only is its charge time an astonishing 30 seconds, it is also a non-contact operation. Therefore, ESL devices containing ORB battery can be charged in situ. More can be read about Organic Radical Battery technology at: http://www.electrochem.org/dl/interface/wtr/wtr05/wtr05_p32-36.pdf.

One final deterrent to rapid acceptance of RFID and ESL in mega-stores and supermarkets, especially in the United States, is corporate culture inertia -- the slow, plodding process of changing "the way things are done" in the retail industry. RFID and ESL technology and devices presently exist in thousands of retail stores and supermarkets in Europe, but only two U.S. supermarket chains have ESL installed, and those are limited to evaluation purposes only. It typically takes a long time to introduce any radical new technologies or processes into the retail business, so it might be a while before RFID and ESL come to your market.

Analyst David Johnson specializes in electronic, magnetic, optic, and electro-optic systems designs, partnering with companies needing expertise to assist their in-house design teams. He analyzes prior art for companies preparing intellectual property disclosures, and is an expert in the design of reliability stress-testing systems and procedures, assisting companies to develop their own reliability testing platforms and procedures.

Nerac analysts deliver custom assessments in the following areas:

- Product and technology development opportunities

- Competitive intelligence

- Intellectual property strategies

- Compliance requirements

- Scientific review and problem-solving