A Day in the Life of an SPIE Professional: Christopher Wilcox

This #FacesofPhotonics article features Christopher Wilcox, electrical engineer at AFRL.

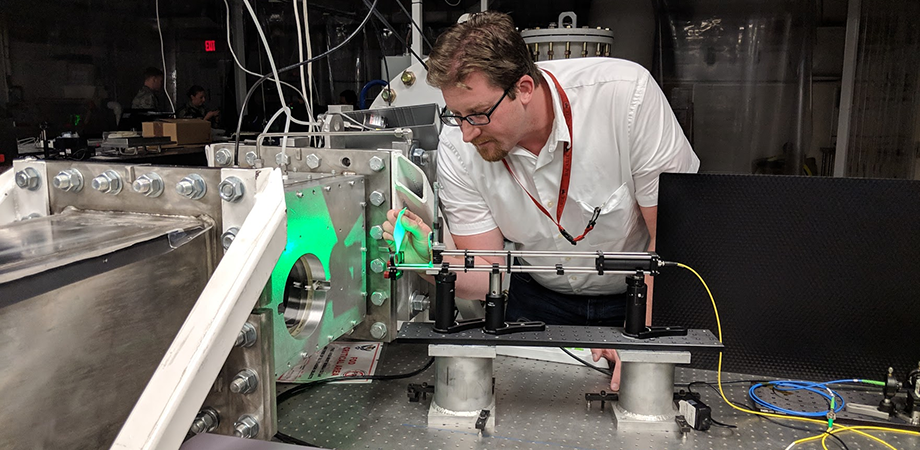

SPIE Senior Member Christopher Wilcox runs the Aero-optical Effects Laboratory (AEL), which includes a wind tunnel capable of supersonic speeds. Optical windows allow his research group to access an 8 in. × 8 in. test section to study the effect of high-speed airflow on aircraft systems with high-energy lasers, laser communications, or imaging equipment that needs to maintain high resolution over very long distances.

Describe a typical day in your lab

Yesterday, I went into my office and checked my work email to see if there were any high-priority items. I had a planned experiment with the AEL wind tunnel for the afternoon, so I went to my lab and checked the alignment of the optical system with a colleague and graduate student, after which we took a quick break for lunch. In the afternoon, my team and I ran the wind tunnel and collected several sets of data for further analysis. The data collected was schlieren imagery, which can image optical inhomogeneities or pressure differences in a transparent material, such as the supersonic flow of air in our wind tunnel. We collected the schlieren image data with a high-speed camera, acquiring the 768 x 768 pixel images at a rate of 25,000 frames per second. Once analyzed and reduced, this data will provide us with a viewing of the shock waves from our experiment in our wind tunnel that were changing at rates much faster than the human eye can detect. After our data collection campaign was complete, we covered our optics, shut down our systems, and broke off for the day.

Share a memorable career story

I was working on a next-generation space telescope as a research fellow at the Naval Postgraduate School. It is a technology demonstrator platform for the James Webb Space Telescope called the Segmented Mirror Telescope. It has six segments of hexagon-shaped adaptive mirrors to make the overall 3.2-m primary mirror telescope. We had a control loop that would modulate each of the 196 actuators of each mirror and measure and build an influence function that could correct for aberrations. The code was complex and running lots of subroutines, and there was a hangup in between a bunch of calculations, so it was taking two to three days to complete! I dug deep into the code to figure out what was going on and was able to attribute the problem to a memory leak that caused the system to hang and eventually resulted in a software crash. We were able to reduce the calibration routine to just two to three hours after that, which hugely increased the fidelity of the system.

How does a person pursue a career working in a government lab?

Many government research labs have programs that students can take advantage of, like the Science, Mathematics, and Research for Transformation (SMART) Scholarship program from the US Department of Defense (DoD). Students pursuing degrees in STEM fields can receive a full scholarship and a job with the DoD after getting a degree. Or, we have the AFRL Summer Scholars program, which offers internships that help you get your foot in the door.

What do you like about working in a government lab?

We have many cutting-edge problems and projects and we get to work with small businesses and universities to help solve those problems. There's a program called Small Business Innovative Research (SBIR), which is a good way for the government to interface with small businesses that may have a good idea that would also be useful in our lab. For example, for the wind tunnel in the AEL, we put out bids for SBIRs that can measure the volume of airflow and take "snapshots" at high rates, essentially measuring the volume of the air that's moving through the test section many times per second. We have several companies working on different approaches to be able to perform this. In supersonic wind tunnels, air is traveling at many hundreds of miles per hour. The update rate for the camera systems has to be very high. It's cutting-edge technology!

Follow #FacesofPhotonics on Instagram, Twitter, and Facebook.

| Enjoy this article? Get similar news in your inbox |

|