Companies offer an inside look into their portfolio of products and services. Find top suppliers, explore product and company capabilities, and build partnerships that will advance your work.

The Moscone Center

747 Howard St

San Francisco, CA 94103

Halls A, B, C, D, E, F

| The Moscone Center | |

| Tuesday 28 January | 10:00 AM—5:00 PM |

| Wednesday 29 January | 10:00 AM—5:00 PM |

| Thursday 30 January | 10:00 AM—4:00 PM |

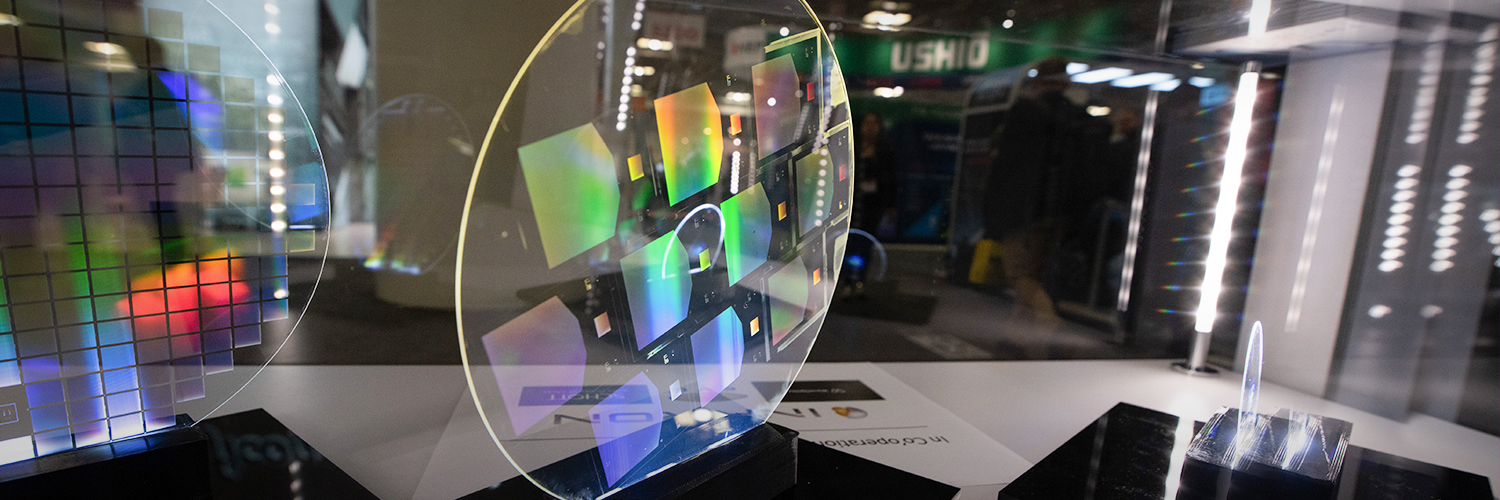

Join us for the SPIE Photonics West Exhibition 2025, the globally recognized event for providers of the best solutions, components, instruments, and system supports for the optics and photonics industry. We look forward to gathering in San Francisco. Learn more about how your company can participate as an exhibitor.